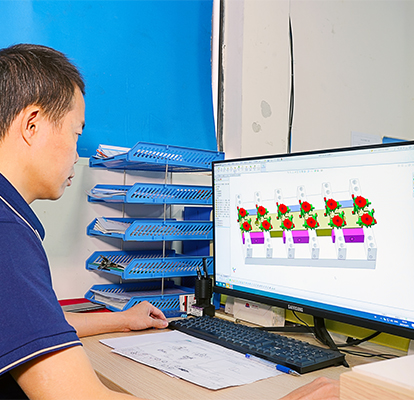

Technical accumulation and quality inheritance

Since its establishment, Sinotekk has always focused on technological breakthroughs and process innovation in the field of precision machining. In over 40000 hours of equipment operation practice, we have built a complete technical system covering material science, CNC programming, and precision testing, serving more than 50 manufacturing enterprises worldwide, with a long-term stable product qualification rate of over 96.63%. This persistent pursuit of precision has established a professional reputation in high-end fields such as automotive manufacturing, medical equipment, and precision electronics.

Frequently asked questions

15 years of CNC manufacturing! 44 units CNC machinery, ±0.005mm precision, IATF16949 certified, 24-hour online response, 48-hour emergency delivery, expertise in automotive/medical/semiconductor. We apply military standards to civilian components, ensuring zero deviation from blueprint to product!

We have built a three-tier quality protection shield:

1. Incoming Material Inspection: Hardness testing

2. Process Quality Control: 6 critical checkpoints per operation

3. Final inspection: Full-dimension report + key characteristics SPC analysis

Certified by IATF16949, we have established an 8D methodology for zero-defect assurance.

We understand the importance of precision manufacturing for customer project timelines and commit to:

- Regular order delivery cycles of 7-10 days (industry average 25 days)

- Emergency orders can activate a green channel (fastest 48-hour delivery)

- Providing process optimization suggestions to help customers reduce costs by 5%-15%

Over the next three years, we will invest 20M CNY ($2.8M ) in intelligent transformation, implementing AI-powered visual inspection systems and automated flexible production lines. We remain committed to advancing new energy vehicle components, aerospace precision parts, and other cutting-edge sectors, aiming to become the Asia-Pacific benchmark for premium precision manufacturing.

Precision CNC machining

Our engineering team is proficient in 36 materials, including titanium alloy, stainless steel, aluminum alloy, and powder metallurgy, excelling in complex surface processing and thin-walled parts processing. Particularly in miniature precision parts (minimum processing size 0.5mm), we possess unique process solutions.